ytgapr09perf525.jpg

Propeller tunnels got a bad name early on, but things are different now. My first encounter with prop tunnels was when I bought a 21-foot PennYan many years ago. I lived just inside Jupiter Inlet, along the Loxahatchee River in South Florida. I wanted a boat that would be capable of running the river’s notorious shallows, yet still be suitable for the occasional offshore fishing trip. Things were fine running wide open or trolling, but at any speed in between, her V-8 sucked enough gas to keep a Texas oil well working overtime.

What was the problem? Well, the design of the tunnel and the specification of the propeller combined to make this a very inefficient ride. PennYan was not the only boat of that era that suffered similar symptoms. Thankfully, we’ve learned quite a bit over the years. Today propeller tunnels can help enhance performance significantly.

The purpose of tunnels remains the same as they did on my old boat: to help reduce the draft. Unfortunately, that goal is at odds with the laws of physics, which hold that a certain amount of propeller blade area is necessary for a certain horsepower, speed, and boat weight. If you don’t have enough blade area, cavitation is the usual result. Cavitation manifests itself as noise, vibration, prop and rudder erosion, and degradation of performance, with increased fuel burn and reduced speed and range.

So how do you achieve the necessary propeller blade area and avoid all the problems? Generally, a larger prop diameter is more efficient than a smaller diameter, so bigger props are the obvious answer. (See “Yacht Yard” on page 80 for more on props.) Putting physics aside for a moment, that extra diameter has a practical downside: It aggravates the draft problem, since propeller tips are the low point on most boats. There’s only so much space for props between the bottom of the boat and the bottom of the sea. We can’t move the bottom of the sea, but we can move the bottom of the boat. This is accomplished with prop tunnels.

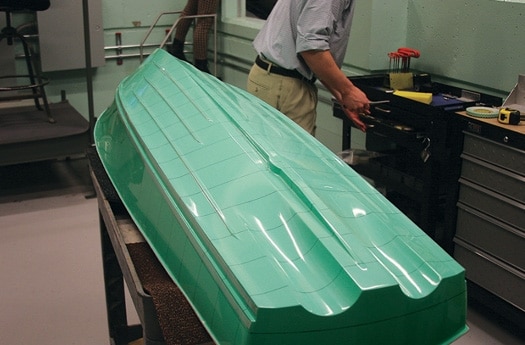

In 1997, writing in Professional BoatBuilder, I offered detailed tunnel guidelines to designers and builders. The guidelines have proven successful over the past ten years and the image on this page is a great example. As a boat buyer rather than a designer, you don’t need all the technical details, but it won’t hurt to know what to look for when shopping for a new boat.

The photo shows a tank-test model of the new Viking 82 Convertible. Some changes were made from the model to the finished boat, but the prop tunnels stayed much the same. The sides of the tunnels are parallel to the centerline of the boat, and parallel to each other as well for their entire length. The sides do not converge either forward or aft. Looking closely at the black lines drawn athwartship, you can see that at the forward end of the tunnel, the shape of the tunnel roof begins very flat, and then transforms into a progressively tighter radius as we move aft toward the transom. At the point of the propeller location, very near the end of the keel on this example, the tunnel reaches its smallest radius. Aft of this point, from prop to transom, the shape can be maintained as in this Viking, or might converge just a bit to create a slight “nozzle” effect on some boats.

In addition to having the right shape for the tunnel, it is important to have the cleanest, most undisturbed water flowing into and out of the tunnel. This is done by avoiding discontinuities in the hull bottom and locating “bottom clutter,” such as thru-hulls and transducers, out of the path of the water flowing into the tunnels. Shaft strut and rudder palms should be mounted flush, in indents molded into the tunnel, if at all possible.

Finally, there’s the question of how close the prop should run to the tunnel walls. On installations without tunnels, the guideline is to allow 15 percent of the prop diameter (4 ½ inches on a 30-inch prop) as clearance between the hull bottom and the prop-blade tips, to avoid excessive vibration. With tunnels, this can easily be tightened up to 5 or 10 percent, and some designers have successfully gone to nearly zero without undue vibration. Obviously, this allows a few more inches of prop diameter (3 to 4 inches more in our example), for more blade area and efficiency, with resultant speed, range, and efficiency gains and without added draft.

So there you have it: reduced draft and fuel usage, more speed and range, less cavitation and vibration. Tunnels aren’t necessary for all boats, but when draft is a problem, they can be the answer.