In the past decade, diesel engines have gained a third more horsepower and burn less fuel to reach it. Repowering with new engines can rekindle the spark in a beloved but aging boat. But the investment also carries a long-term commitment to that boat, and projects often include not just new engines but also updates to many ship’s systems. A quicker, less costly option is to overhaul engines without added horsepower. But it is sometimes possible to increase horsepower while doing the overhaul. To explore the pros and cons of all three options, we turned to engine manufacturers and mechanics.

A good example of the options comes from Cummins MerCruiser Diesel’s QSM11 engine (www.cmdmarine.com). Before 2002 this engine topped out at 635 horsepower, but was common at 580 or 535 horsepower. Today it’s available up to 715 horsepower. “[Increasing horsepower] could be as simple as loading a new calibration,” says Dan Burns, an engineering manager with CMD. “If you have a 580 and want 635, it’s just software. [We] plug in a laptop, load the new calibration and change the data plate.” If the engine is still under warranty, CMD’s up-charge would be around $10,000, but once beyond warranty the new calibration software with installation costs under $500 per engine. The rationale is that the manufacturer would prefer to do the upgrade once its warranty responsibility has expired. All systems from fuel and air entering the engineroom to exhaust and propeller-shaft size need to be scrutinized for adequacy at the higher horsepower, and even modest power increases are best done in conjunction with an overhaul when engine parts are fresh. Horsepower increases also have to be documented as meeting engine- and boatemissions requirements, complete with a new factoryprovided data plate affixed to the engine.

Upgraded engine components are often needed as well. Raising a 535-horsepower QSM11 to either 580 or 635 requires a new turbocharger—a $1,750 part that might be replaced in an overhaul anyway. Reaching 715 horsepower is also possible. New pistons, injectors, camshaft, oil pan, and other components are needed. “The added benefit you’d get in performance may not be worth what it would cost you,” Burns says. “For a 35-knot boat, increasing from 635 horsepower to 715 you’d gain a knot or two.” On the other hand, a modestly powered boat could see quite a change. “Sometimes 3/4 of a knot will get a boat to lay down flatter and really change hull efficiency,” Burns says. “You thought you were on plane, but maybe you weren’t quite over the hump.” For a boat that performs noticeably better by running engines a bit harder than rated cruise rpm, a bump in horsepower could be a big difference.

Click to enlarge.

Deciding whether to rebuild, repower, or modify existing engines depends upon the desired outcome. “What is it that you dislike about your boat?” Burns asks. If performance is fine with older mechanically governed engines, but you want cleaner exhaust or lower noise, consider a repower. “On a fishing boat, when you’re trolling with mechanical engines, you’ll smell that exhaust all day,” Burns says, “But when you go to electronic, you won’t have that.” Smoke when starting or accelerating and soot on the transom at the end of a day are reduced with new electronic engines. But if fuel mileage is the issue, a simple switch from mechanical to electronic might be disappointing. “Going from a 370B mechanical engine to a QSB380, you’ll see an increase in economy, but probably only five percent,” Burns says.

Boats with older two-cycle Detroit Diesel engines are ideal to repower with today’s smaller, lighter, more fuel-efficient engines. One example is a 1981 50 Hatteras Convertible with 575-horsepower 8V92 Detroit Diesels repowered with 715-horsepower QSM11s. The boat originally hit 23 knots and cruised at 18 knots, burning about three gallons of fuel per mile traveled. The new engines top out at 27 knots and cruise at 22 knots, using 2.2 gallons of fuel per mile. At 18 knots the new Cummins burn just 1.6 gallons per mile. The inline six-cylinder engines lightened the boat by over a ton and opened up a previously cramped engineroom. Because horsepower was similar, exhausts were adequate, and new props were the only change made to the boat’s running gear, keeping costs down.

While Cummins made few changes from one model year to the next, other manufacturers’ engines evolved over time. “If you have a C32 purchased as 1,550 horsepower, you can upgrade to 1,650 with just a software change,” says Mike Kirkman, technical communicator for Gregory Poole Marine Power in North Carolina, a Caterpillar distributor (www.gregorypoole.com). But the Caterpillar 3412C started as an electronic engine at 1,100 horsepower in 1995. It increased to 1,250 and then 1,350 horsepower over the next five years. Upgrading is possible, but required components vary as much by year built as original horsepower. “We’ll research it and see what it will take,” Kirkman says, “Then you can weigh your options.” Switching from mechanical to electronic engines typically isn’t practical, but mechanical engines can often be upgraded. “That 3412C was originally 900 horsepower [with a mechanical governor and twin turbos], and 750 horsepower as a single turbocharger engine,” Kirkman says. That same mechanical engine eventually reached 1,000 horsepower—a possible upgrade during the course of an overhaul.

Mechanically governed two-cycle Detroit Diesels can see noticeable increases. “The 8V92 was originally 575 horsepower, but it had a 12V71 heat exchanger and dry turbos,” says Charlie Schloemer, president of Palm Beach Power in West Palm Beach (palmbeachpower.com). With a new cooling system, water-cooled turbochargers, and other parts, that same engine became 650 and then 735 horsepower before switching to an electronic fuel system.

The marriage of MTU engines with Detroit Diesel Electronic Controls in the late 1980s helped the basic 12-cylinder MTU 183 block evolve from 1,150 horsepower before electronics into the 1,920-horsepower 12-cylinder Series 2000 engine today (www.mtudetroitdiesel.com). But that evolution occurred with so many minor component tweaks that increasing horsepower of MTU engines isn’t feasible. “They’re learning as time goes on. That’s how these improvements happen,” Schloemer says. MTU also learns through a well-defined maintenance program. “If the customer follows the program, every 500 hours we’re into something on that engine,” he says. “We’re going to catch a problem early. That’s why these things hold up so well.” MTU schedules overhauls between 4,000 and 9,000 hours, depending on model.

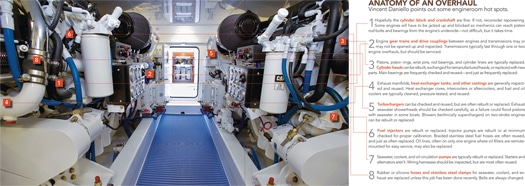

Schloemer, Burns, and Kirkman all say that a specific, identifiable failure like a faulty injector or valve can cause damage requiring the replacement of just one or two cylinders. Schloemer says he’s found fuel or air restrictions, broken components in the exhaust causing backpressure, or turbochargers eroded by a steady diet of salt air, all mistaken for tired engines—to the relief of owners expecting overhauls. But even when rebuilding engines becomes the obvious choice, mechanics differ on which parts will be reused, rebuilt, or replaced. “There are critical engine components that [if they fail] could trash your entire rebuild,” Kirkman says, citing injectors and coolers. “Some people put the same fuel lines and cooling hoses back on. They may be fine, but you have to hope they don’t cause a problem a year down the line,” he says. “The whole reason you’re going through this process is to have a reliable engine that you can take to sea and not worry.”

Many of these items come down to owner preference and budget, but problems arise when comparing contractors. “Each customer is different. I ask up front how they want to go,” Schloemer says. “I specify in my quote what will be exchanged, rebuilt, serviced, or replaced with new parts.” But many don’t. Parts with wide variation include main bearings, turbochargers, pumps for seawater, fresh water, and oil, and cooling- system components. Cylinder kits and heads, piston rod bearings, and injectors are replaced by most reputable mechanics. Starters and alternators typically aren’t.

Warranties need to be considered. Palm Beach Power offers a 12-month warranty on parts and workmanship, but many mechanics provide 12 months on parts, with a six- or three-month warranty on workmanship. Caterpillar offers Overhaul Protection Coverage, a rigorous overhaul and inspection process, and sells warranty coverage for five years. Cummins MerCruiser offers some models as completely reconditioned engines for repower or in place of overhauls, typically for around 30 percent less than new engines and including a two-year warranty on parts, labor, and travel.

The choices for specific engines in a given hull are complex, but only because technology has provided many new options to improve our aging yachts.

Read more about Diesel Electric Drive or the Evolution of the Detroit Diesel Engine.