Trumpy1inside.jpg

Ever look at your boat and think: She deserves better? Time and wear and tear have taken their toll, and preventive maintenance just isn’t cutting it any more. You need to do a full restoration or refit.

Whether you want to do a complete refit or just refurbish one part of your boat, the proper approach to the project is remarkably similar. We thought the best way to show how it’s done was to follow a refit from start to finish.

Fortunately, a project presented itself when Jock West, a marine publishing and marketing veteran, suggested that Yachting be the exclusive media partner in the restoration of Showtime, a 63-foot 1969 Trumpy. West wanted to provide an exciting alternative for clients, such as Interlux paint and Awlgrip, to show their products in use.

“Paint in a can is very boring,” West explained. “Doing it on a cool boat like Showtime is not.”

Yachting is observing and documenting the refit every step of the way. The staff will also get use of the vessel to explore editorial opportunities, including the East Coast boat show circuit. Expert marine photographer Billy Black will preserve the visual record.

Planning the Refit

Once West made the decision to embark on this project, he needed to get the right project manager to lay out a plan and make sure everything followed it. Every screw, wire, valve, bulkhead, beam, corner piece, and fitting-and the order with which they are dealt-would be his responsibility. So West enlisted the services of Steve Anderson, president of J&J Marine in Somerset, Massachusetts.

“For us, there was no other choice,” said West. “Steve and his crew are at the top of the list and given our out-of-water schedule-six weeks-I knew that she would be ready.” Anderson is a personable man with an encyclopedic knowledge of boat repair and refit.

“When we agreed to take this on months ago, the first thing we did was jump in the car in the middle of the winter and drive up to Syracuse, New York, where the boat was being kept,” said Anderson. “That day gave us the right perspective to plan the six-week work schedule. She was well cared for over the years and by the time we got back to the yard, I knew how we were going to approach the project.”

Given the unusual time constraints, Anderson decided to involve teams of specialists, including cabinetmakers, electricians, shipwrights, painters, and sanders and finishers, who would descend on the yacht en masse the day after she was hauled.

The project manager met with West numerous times over four months and together they developed the work list. Anderson’s meticulous research helped him decide whom he would tap to do each part of the project. West had also brought a wish list to the table and it wasn’t long before they had decided on the bids and personnel.

“Getting the work list together so we could gauge how much this was going to cost was one of the key steps in the process,” Anderson said. “Getting it right at the beginning would mean success at the end.”

I was there when Anderson met with master carpenter Kevin Coristine, who would be handling the galley makeover, and Steve Smith, Awlgrip’s key accounts vice president. Projects like this one generate a certain passion in those involved, and they had shown up to see how the haul was going and to discuss their roles.

“For us, it’s going to be a matter of restoration for preservation,” said Coristine as he unrolled several drawings and measurements he had already taken of the galley area. “The goal here is to keep things pretty much the way they are so that when you come into this space, it’ll be like it was when the boat was first built.”

To that end, Coristine and his crew will be refacing many of the cabinet doors and drawers, replacing any missing or broken hardware, stripping off the old wallpaper, putting in new countertops, and laying down a new rubber galley sole. “If we can’t find it, we’ll make it,” he said. “There’s beautiful wood aboard this boat and all most of it needs is some TLC.”

Smith had nailed down specifics in describing his role in the project. “For the varnished surfaces, we’ll be taking everything down to bare wood and starting over from there. Our Awlspar classic spar varnish and Awlbrite clear acrylic urethane will take care of the rest,” he said. “As far as the painted areas, we’ll carefully prep those surfaces and get it all covered with our Awlbrite semi-gloss,” he added as we looked out at the cold, gray day. Almost reading my mind, he said, “She’ll be indoors by the time we’ve finished with our prep work so we can control temperature and humidity as well as wind and weather.”

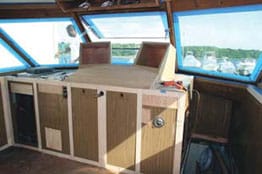

Anderson will also be donning the coveralls, as he and his crew will be renovating the wheelhouse. “I plan to retro the space with a Victorian look using Honduran woods, leather coverings, specific moldings, and other materials and fabrics to get what we want,” Anderson said. There will also be some functional changes to the helm to accommodate the updated array of new electronics.

|

| | |

Hauling Out

Hauling a boat is never an easy task. It takes a coordinated effort among the yard personnel to make sure everything goes right. And with a wooden boat almost 40 years old, the undertaking operates under one key philosophy: slow and easy. Once the operation began and she was moved into position, it took well over an hour of test lifting, adjusting the straps, and lifting again, before Showtime was given the green light. Under the watchful eyes of J&J’s yard operations manager Jeff Almeda, she was gently taken out of the water and just as carefully, placed on the hard.

Next Steps

The rest of Anderson’s crew arrived the next day and began the work in earnest: -Imtra designed and installed LED lighting as well as new wipers and motors. -F.W. Murphy customized a sender package so her original twin 1969 Detroit Diesel 671NA diesels can have digital readouts in the pilothouse. –Installation of the teak-and-holly companionway and pilothouse sole was initiated. –The windlass will be removed and overhauled, including rewiring and replating, and then be reinstalled. –Original chairs and furniture will be refurbished and all cushions and seats will get new navy upholstery with red piping. –The 13-foot Boston Whaler, on loan to West’s grandkids for the summer, will be replaced by a new lightweight Zodiac RIB.

Because she was well cared for below the waterline, Anderson could find no more than about 300 screws needing replacement to refasten her hull. But three planks are to be replaced and there is a necessary repair being done to her starboard quarter at the waterline before her bottom paint is applied.

Obviously, a job like this is big. But if the project is broken down on a work list and attacked as small pieces, it becomes much easier to handle. The project manager-who may be the yacht owner, in some cases-monitors each task on the list, and keeps everything moving forward.

This is the first in a series of articles covering the refit of Showtime. Next month, I help with some brightwork and check on the overall progress. – K.K.