ytgjan09yyairsep525.jpg

Owners of yachts powered by today’s diesel engines now reap the benefits of running a finely tuned machine. But with that reliability, horsepower, and clean running come precise tolerances and computerized engine controls that need care and feeding-and expert service personnel when things go south.

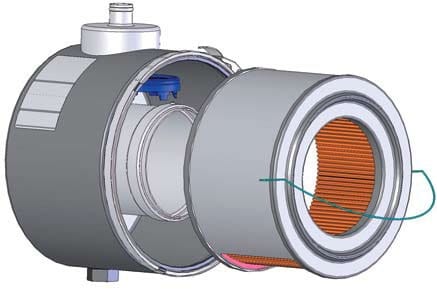

Understanding why your diesel runs cleaner will help you to keep it that way. Many engines emit far fewer harmful gases in the engineroom now thanks to a system called the Walker AirSep Air/Oil Separator. If your engine has one, you need to keep it working right. And if your engine doesn’t, you may want to look into adding one. Here’s what you need to know.

After developing a similar device for the U.S. Navy in the 1980s, Walker Engineering introduced the AirSep Air/Oil Separator to the recreational marine market, and in 1989 it quickly became standard equipment on Detroit Diesel engines. In 1992, Caterpillar made them standard on certain models, including 3116, 3126, 3406, and 3412, as did Alaska Diesel. Cummins followed suit in 1994. And as the engines have evolved, the AirSep has changed with the times. They now have a more effective silencer feature, but the basic technology has remained the same.

The military applications, mainly for Detroit Diesel products, came about from an interest in reducing crankcase pressure for better performance and less chance of oil leaks, as well as eliminating the crankcase fumes from the engineroom for crew health and safety.

“The work on the [Detroit Diesel] engines led to the AirSep system being supplied to Detroit engines on Viking Yachts,” said Mike DeLillo, vice president of sales and marketing for Walker Engineering. “The improvement in engineroom cleanliness, and the elimination of noxious fumes for family and guests was a natural progression in improving comfort onboard.” The then-chairman of Detroit Diesel, Roger Penske, endorsed the addition of the AirSep system to marine diesels as standard equipment, following engineering evaluation and testing.

To understand what the AirSep does, you first need to understand how your diesel engine works. Whether an engine has an open- or closed-crankcase system, internal combustion engines share a common problem: excessive crankcase fumes. Open systems, venting to a stock filter in the engine breather, present a problem when blow-by gases enter the crankcase, but also escape into the atmosphere, carrying with them a witch’s brew of additional pollutants.

| | |

Blow-by occurs when the compressed air and fuel mixture on top of the cylinders, along with some lube oil, gets by the piston rings and into the crankcase. This happens in all engines, but worn rings allow more blowby. The gases-a mixture of water vapor, unburned fuel, atomized oil, particulate matter, and soot-mix with the oil lubricating the crankshaft, and then are typically vented out of the engine through a valve-cover breather. The mixture coats equipment, making the engineroom a greasy mess. Even worse, it can leak down in the bilge and eventually get pumped overboard. Not good.

With most open systems, the crankcase fumes are recirculated back into the combustion air stream at the air filter. But while the blow-by does not get released completely into the atmosphere, it does get redirected. That means precision parts like the turbocharger and intercooler are now exposed to the contaminants and may be coated with them, and hampered from operating at optimum efficiency if buildup occurs. This in turn will affect fuel burn and engine-load effectiveness, create wear and tear on critical parts, and increase oil use.

By creating a closed-crankcase system, the AirSep is able to prevent crankcase pollutants from escaping in the engineroom and turbocharger.

“The result is a reduction of crankcase pressure, allowing the engine to operate in a vacuum,” said DeLillo. “Elimination of seal leaks, less lube oil being forced by the rings into the cylinders, and a reduction of oil being vented from the crankcase are some of the direct benefits of the system.”

During engine operation, the AirSep pulls the combined blow-by from your crankcase breather and separates the oil from the volatile, fuel-rich gases. The cleaned combustible gases and water vapor are then inducted into the engine’s airintake system for recombustion. Finally, the recovered lube oil is returned to the crankcase. On turbocharged and aftercooled engines, removing the lube oil from the blowby gases and reintroducing the leftover water vapor and raw diesel fuel into the air intake helps prevent harmful grit and deposits from accumulating on the turbo blades, or oil residue collecting in the aftercooler. In addition, the inducted water vapor helps to lower combustion temperature, allowing the engine to run more efficiently.

| | |

Any diesel engine, whether naturally aspirated or turbocharged, can be retrofitted with an AirSep. There are even kits for small marine gensets, and auxiliary engines for sailboats. Supply the make, model, and horsepower of your engine and a Walker supplier can recommend a suitable kit. Kits are sized according to engines to deliver the proper vacuum and airflow.

The wide variety of kits made by Walker can retrofit any Cat, Yanmar, John Deere, MAN, MTU, Alaska Diesel, Ford Lehman, Perkins, Hino, and Deutz in marine propulsion or genset applications. One of the company’s latest products is a disposable AirSep designed for the 1.7-liter Mercruiser diesel. Lastly Walker has a full line of custom adapters and other parts to complete installation on any engine, no matter how old.

With some of the aforementioned benefits, especially cutting down the wear and tear on critical parts, older engines will be able to continue cranking the hour meter and even extend the time between rebuilds.

Whether the Walker AirSep came as standard equipment on your diesel engine or was added in a retrofit, the clean operation and improved performance, as well as extended engine life, are benefits every yachtsman should want. Simple maintenance will keep the AirSep working like it should.

Walker Engineering, (818) 252-7788; www.walkerairsep.com