ytgjan26yy525.jpg

I am often asked about engine maintenance schedules, but seldom hear questions about marine transmissions. With proper service, marine transmissions will cause few, if any, problems through many thousands of service hours. If neglected, though, they may leave a working engine with no way to transfer power to the propeller. A transmission problem can be devious: When an engine fails, the propeller stops spinning, but a neglected transmission could lock into forward or reverse. Even Murphy’s Law skeptics have to concede this is most likely to happen while docking, and the result could be ugly.

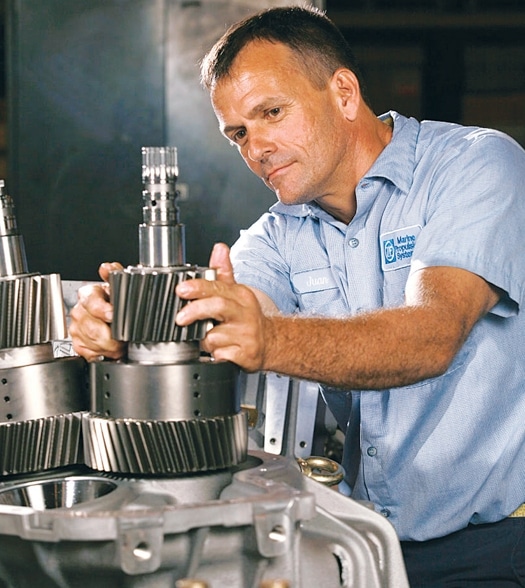

“A lot of people lump the transmission in with the engine. They don’t see the two as separate components,” says Martin Meissner, marketing manager for ZF Marine (www.zf.com). “They’ll call Cat, MAN, MTU for service, but they don’t realize that [often] the transmission isn’t being done.” People accustomed to automobile maintenance, where all service is performed by the dealership, may not realize a boat’s propulsion may require two different mechanics. “A factory-trained technician knows what to look for, and can make sure everything is within specification,” Meissner says.

Another reason some boaters ignore their transmissions is that the oil always looks clean, but looks can be deceiving. “Those clutch packs are sacrificial,” explains Meissner. “The moment the transmission is going into gear there is a certain amount of slippage as [the clutch plates] come together. Once they’re locked up they stop slipping [on a properly working transmission]. They wear over time and you’re circulating this material through the transmission and increasing wear.”

Transmission clutch plates are designed to last many tens of thousands of hours, even factoring this wear, but oil contaminants can cause more immediate problems. “You get particulates in the oil, copper and lead from clutches, and iron from bearings,” says Fred Brunn, owner of American Marine Tech in Palm Beach Gardens, Florida (www.amti-inc.com). Brunn is factory-certified to repair ZF and other transmission and engine brands. “Eventually you clog the filter and that affects clutch pressure. It will eventually slip and could disengage,” he says. Brunn also says slipping clutches can heat up to the point of damage. “When the plates get hot they can fuse together and lock in forward,” he says. “Nobody notices until they get to the dock and take it out of gear, but then the engine won’t go into neutral.”

Brunn often sees even the outsides of marine transmissions neglected, resulting in preventable failures. Oil or seawater dripping onto the transmission can gum up or corrode vital shift linkages and shift-control components. Abrasive salt and rust can also wear the transmission output seal, sometimes necessitating the dismantling of the transmission for repair. Neglect can take its toll internally as well. Transmission oil cooler zincs should be changed along with engine zincs, and coolers should be cleaned and tested when engine cooling systems are serviced, or risk having the transmission fluid disappear overboard through the cooler. “On larger gearboxes [beginning at roughly 1,000 horsepower], the cooler is integral to the transmission,” Brunn says. “If you ignore service on these you can get into big [and expensive] problems with the aluminum housing.”

Even with proper maintenance, marine transmissions occasionally fail. But they often slip, shift harder than usual, or make uncharacteristic noises well beforehand. “If there is a change from normal for your gearbox or your boat, that’s a warning,” Brunn says. Many problems can also be detected by monitoring transmission oil and temperature. “Oil should always reach at least the minimum operating pressure,” Brunn says, noting that it is typically stamped on a plate on the transmission. “If the pressure drops, either something is wrong hydraulically, or something is coming apart mechanically. It’s the domino effect. One part could make another go bad.”

Transmission oil pressure remains roughly the same when the engine is in gear, whether at idle or full rpm. Oil temperature varies with propeller load and seawater temperature, but should also be monitored for uncharacteristic change. “The majority of transmissions run cooler than they are designed to run,” Brunn says. “On average we see 120 to 140 degrees. As long as it’s below the maximum allowable, typically 180 degrees, it’s okay, but if it starts going higher than normal, say 165, you might need to get your cooler cleaned or you might have a seawater flow problem.”

Slipping clutches also heat transmission oil. Over time, this can be seen right on the dipstick. “Instead of being that nice amber color, [the oil] will start to look like molasses,” says David Richardson, a sales representative for Twin Disc (www.twindisc.com). “When the clutches start to really slip, it could turn black.” One sign of clutch problems is a propeller shaft that turns when the engine is in neutral and the boat is stationary. “As they heat up and cool, instead of being flat, the clutches become distorted,” Richardson explains. The result is a transmission that never completely disengages. “When you put the boat in neutral, you’ll see the propeller shaft still turning slowly,” he says. “There should be no movement of the propeller in neutral unless it is being affected [by current or the boat’s forward motion].”

Trolling valves, which intentionally cause transmission slip to slow shaft rpm below idle speed, don’t increase transmission maintenance, but scheduled maintenance takes on added importance. Older, mechanical trolling valves shouldn’t be operated above their rated maximum rpm or used while docking where immediate power may be needed. With electronic controls, however, some transmissions allow seemingly infinite control, such as ZF’s SmartCommand controls or Twin Disc’s Quick Shift system.

“With Quick Shift, we’re applying less pressure to the clutches and diverting the extra oil to the cooling system to dissipate the heat,” says Richardson. “In Express Mode, in the first 15 degrees of travel [of the throttle lever], you can control that prop to as low as three or five rpm. Once you pass that 15 degrees, you’re in normal full lockup.” Because these work by allowing transmission slip, maintenance concerns are similar to trolling valves.

Transmission service intervals vary, but they’re generally at least twice that of engine oil change recommendations. Filters may be internal or external, and oil selection also varies. “Transmissions are designed with a certain clutch material and size, and a certain oil and pressure to transmit torque without slip,” Richardson says. To develop the proper friction, most models warn against synthetic oil, and many against multigrade oils. Check either the nomenclature plate on the transmission or the manual to be sure.

“Some people never look at the owner’s manual for their transmissions,” says Brunn. “That tells you what you need to do. It’s a piece of machinery that needs maintenance just like the engine. If you ignore it, it will fail earlier. You might be stuck in forward, you could have nothing.” In short, if you ignore a marine transmission, sooner or later it will ignore you.

For a transmission maintenance guide click here.