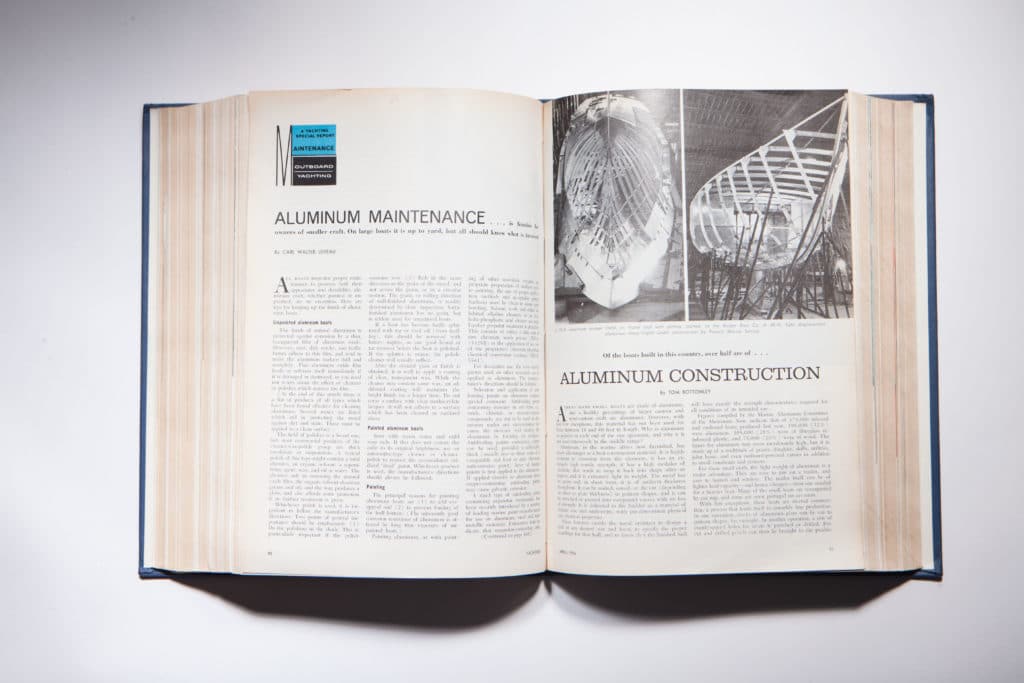

In 1965, the Marine Aluminum Committee of the Aluminum Association trade group revealed that slightly more than 52 percent of the 378,000 inboard- and outboard-powered boats constructed that year were aluminum, including larger custom builds, dinghies, prams, skiffs, jon boats and more.

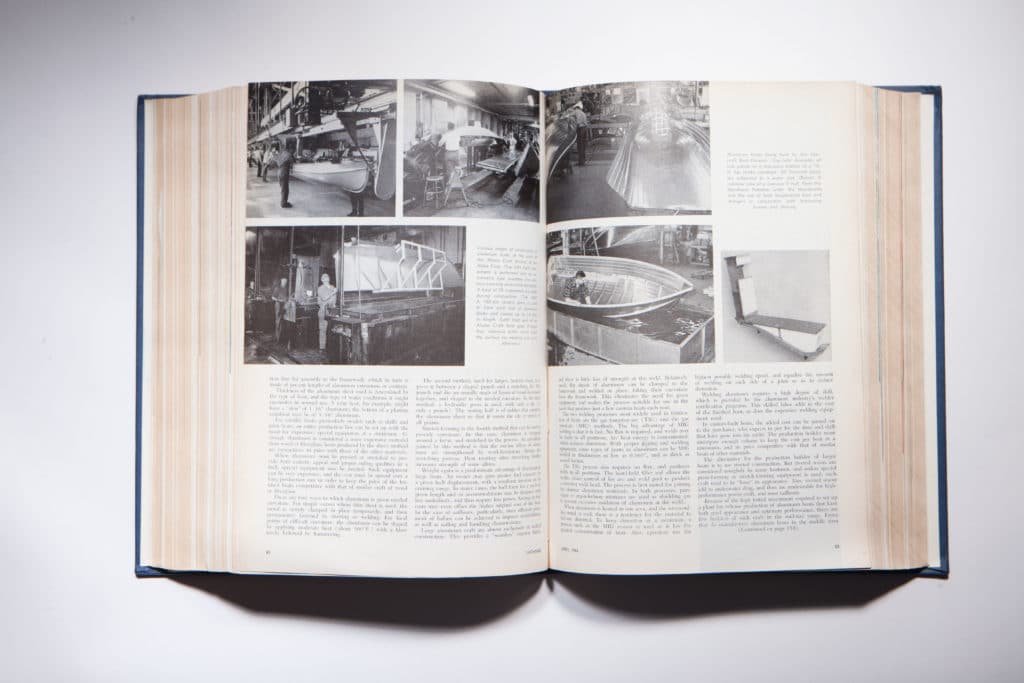

The proliferation of the material’s use in boatbuilding led to Yachting’s April 1966 article “Aluminum Construction.” The metal served as an appealing alternative to wood and fiberglass. Assembly line-style production kept prices comparatively competitive for smaller builds, with arguably easier usage by owners. “For these small craft, the light weight of aluminum is a major advantage. They are easy to launch and retrieve.”

At the time, there wasn’t enough volume for measurable cost savings in the midsize boat business. An alternative was to use riveted construction, but the article states, “Riveted seams are considered unsightly by most boatmen … such craft tend to be boxy in appearance.”

Aluminum construction marked a shift in boatbuilding that’s still felt today. Renowned go-fast builder Don Aronow said at the time, “[Aluminum] is the material of the future in boatbuilding.”

“Because of the high initial investment required to set up a plant for volume production of aluminum boats there are few builders of such craft in the midsize range.”

“Aluminum construction,” Yachting, APRIL 1966