Jamestown Boat Yard took a risk when it purchased a 2004 Grand Banks Eastbay 58 and began carefully to restore it to as-new condition. Designed by C. Raymond Hunt Associates, this model was the grande dame of the Eastbay line, combining the speed and seakeeping ability yachtsmen expect from the designer with the fine quality everyone has learned to expect from Grand Banks. The EB 58’s general arrangement plan invites extended cruises and contains all the conveniences you’d need to live comfortably aboard for as long as you like. Too bad that Grand Banks stopped building the model in 2005, after launching eight examples, and then destroyed the molds. If scarcity adds value to an object, a used Eastbay 58 is a good value.

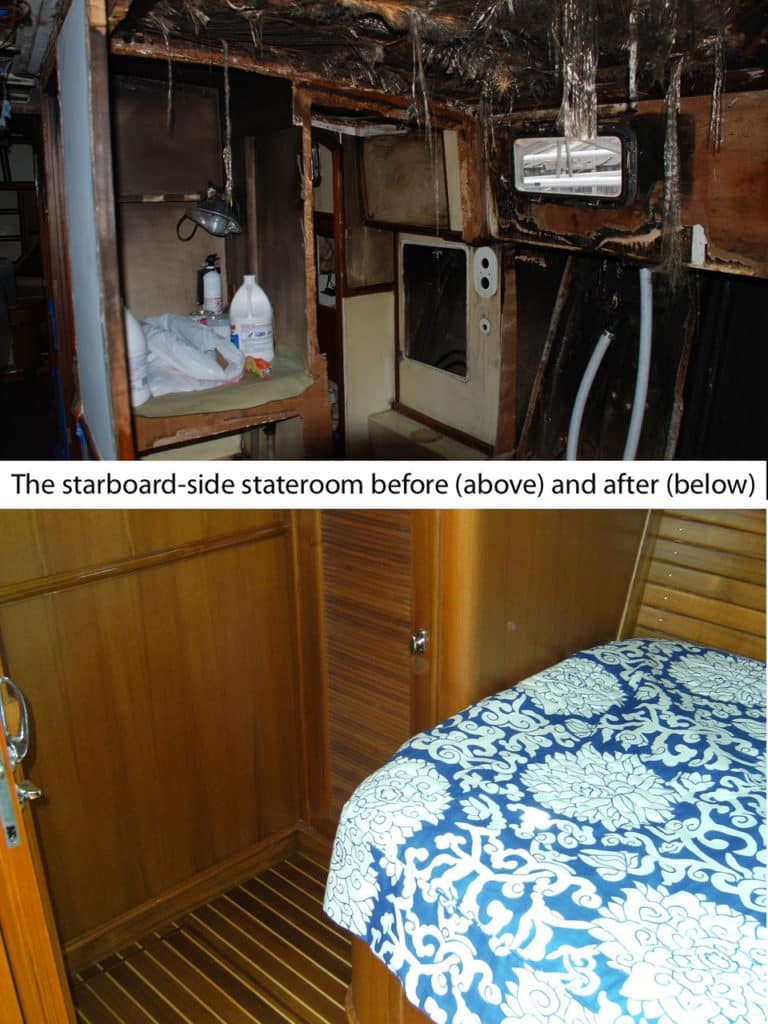

What about the risk? In 2008, this EB 58, the sixth of the line, suffered a small fire. A capacitor on the air-conditioner’s air handler under the double berth in the guest stateroom overheated, exploded and started the fire. The capacitor wasn’t housed in a steel jacket, as is common now. This stateroom is on the starboard side just forward of the helm and down a few steps from the salon. Quick action by the local fire department confined the flames to the immediate area and prevented structural damage to the hull. The extremely hot smoke from this fire, however, caused the vast majority of the cosmetic damage and destroyed much of the wiring above the level of the cabin soles. The firefighters damaged some cabinetry and sections of bulkheads as they searched for smoldering core material and wiring insulation.

A preliminary survey indicated that the yacht was structurally sound. The smoke and fire stayed well clear of the engine room, as did the water used to extinguish the flames. The bilge pumps beneath the sole of the master stateroom kept pace with the firemen’s hoses and prevented any water from flooding into that area. Although the fire created a substantial mess and would discourage the bravest of owners, the crew at Jamestown Boat Yard, in Jamestown, Rhode Island, took on the restoration — something akin to a new build. The yard hired Tony Knowles, of Newport Marine Surveyors, to help assess the extent of the damage and to consult periodically during the repair, and he stayed with the project until the end. This October, he filed his final report, along with a colleague’s survey of the electrical system. The result of the yard’s work, much of which head carpenter Carl Rossi oversaw or performed, is excellent. In the category of not so obvious is the list of new, and often updated, equipment the yard installed.

The thoroughness and quality of the yard crew’s work remind me of a frame-off restoration of a classic car that’s meant to be shown, not used. This Eastbay 58, though, won’t appear in any concours d’elegance. She’s meant for the sea and is for sale for $1,250,000.

Work began in the starboard-side stateroom and the galley opposite. The first order of business was to gut the stateroom and expose the inside of the laminate as it would have appeared during the original construction at Grand Banks. The mattress had rested on a cored-plywood base, cut into sections to allow access to a pair of stainless-steel water tanks, their fittings and hoses, wiring and the air handler. Teak ceilings dressed the inside of the hull in this typically classical interior. All this added fuel to the fire.

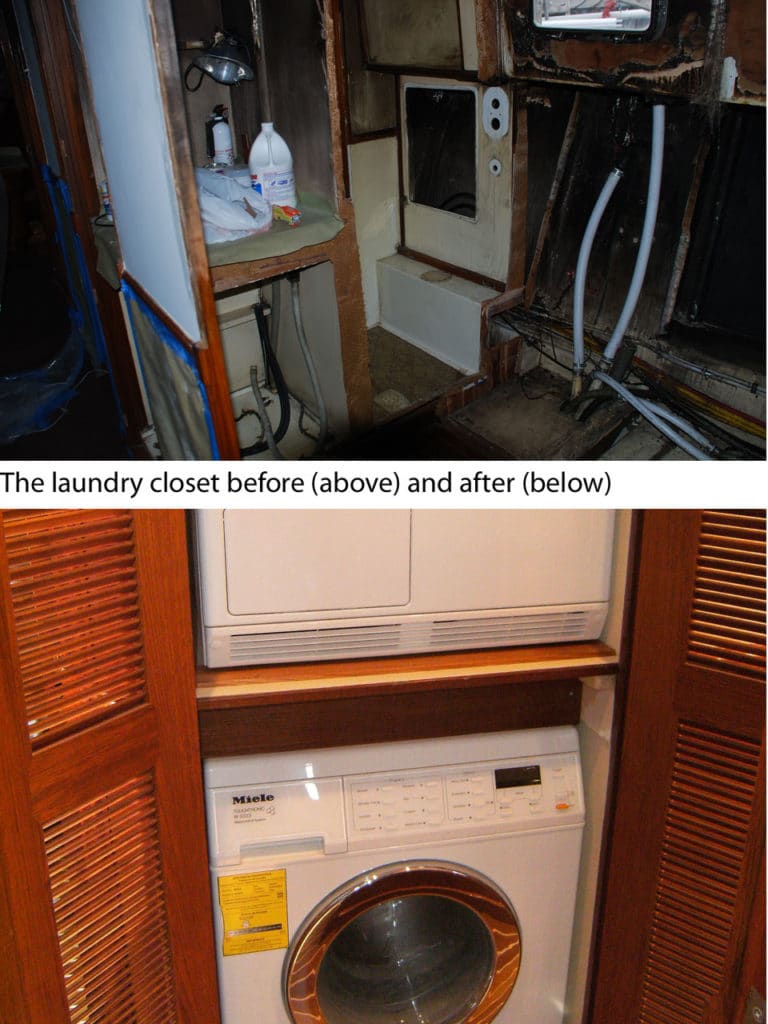

The bulkhead that separated this stateroom from the guest/day head and the full-height cabinet that housed the stacked washer and dryer had to be cut away entirely, leaving only enough space to provide a tabbing surface for bonding in the new panel. (Tabbing is placing strips of fiberglass over the joint and bedding it in resin — epoxy aboard this EB 58.) The laminate behind the burned-out ceiling had been subjected to extreme heat, enough to burn the inner layer and the core, but the outer skin was intact and sound.

Knowles had taken samples of the core material from a variety of places to determine how much of the interior skin and core had to be removed from any given area. In order to repair a damaged section of laminate, the crew had to make sure they were abutting a completely sound area.

After removing the inner skin and core material, workers cleaned the exposed inner surface of the outer skin and roughened it to encourage a good bond. Next, the team vacuum-bagged new coring into place, using epoxy resin. Bonding a new inner skin and feathering it into the surrounding area was the final step.

Epoxy resin has vastly improved the strength of repairs to composite panels, because it is a superior adhesive and takes out most of the doubt of how strong a secondary bond will be. Whereas a primary bond is the result of the chemical reaction among the materials in the laminate during the curing process, a secondary bond is the adhesive joining of two laminates that have already cured. (An example is tabbing a bulkhead into a hull after both have cured.) JBY’s crew replaced the bulkhead between the burned-out stateroom and the guest head by tabbing in a new one made in the yard’s laminate shop. The bulkhead in question has very little stress on it, so a secondary bond, which is about 80 percent as strong as the primary bond, will last a lifetime.

Construction drawings from Grand Banks allowed JBY to reconstruct the woodwork to the exact dimensions and appearance of the original build. Superheated smoke scorched quite a lot of the teak veneer but left the material beneath undamaged. JBY bought the veneer for this project directly from Grand Banks, so the hue and quality of the grain is exactly the same as you’ll find on a new boat. The yard also was able to buy from Grand Banks most of the shapely moldings that create a lovely transition from one flat panel to another. Only one of these wasn’t available, so JBY hired a local machine shop to make a special router bit so the wood shop could duplicate this particular molding’s shape.

Lockers immediately above the head of the guest berth acted a bit like a chimney, drawing extreme heat to the helm console located above and inches abaft the stateroom. All of the electronics and their wiring were trashed. In spite of the damage at the helm, the JBY crew was able to drive the boat north along the Intracoastal Waterway and eventually to Jamestown, using a handheld GPS and VHF. All of the equipment at the helm is new.

Most of the Stidd chair at the helm melted to its framework, and the overhead in the salon smoldered in the superheated smoke. After stripping the damaged overhead from the salon, the workmen had to grind away all of the smoke-blackened areas to eliminate any possibility of having the smell of smoke haunt the yacht after they’d completed their work. “One of the things that amazed me,” Tony Knowles said, “[is] you don’t smell smoke, even after the boat’s been closed up for a few days.” He assured me that this is a very good sign that JBY got the reconditioning correct.

Clem Napolitano, one of the partners in JBY, knew from the beginning that this EB 58, no matter how thoroughly and expertly restored she is, will carry the stigma of “damaged goods.” In the spirit of a perfectionist, he left nothing to chance. All the appliances are new, except the oven, which received a new control panel. All of the hatches and portlights are new, even though some were not damaged; all of the electrical outlets, lighting fixtures, switches and wiring are new; the windshield-wiper motors, which live behind the soffit in the pilothouse and weren’t damaged, are new.

Although the engine room remained untouched by the fire and the extinguishing water, JBY replaced the turbochargers and intercoolers with upgraded models, raw-water impellers, batteries, breaker panels, tank monitors and on and on (view a partial list of replacement parts). To add an exclamation point to the restoration, a representative from Caterpillar recertified the 1,550 horsepower engines for an extended factory warranty.

I saw this EB 58 for the first time in September 2011 at the Newport Brokerage Show. I thought it was a new boat until someone reminded me that the model is no longer in production. She’s a wonderful boat, her warm and intelligently designed interior captivating everyone who sets foot aboard. In October, I spent most of a day with Napolitano and Bob Peckam, of Milton Cat in Milton, Massachusetts, observing the process of certifying the engines for extended warranty, and became attached to the boat after I took the helm for our return to the yard. I was ready to move aboard.

Jamestown Boat Yard, 401-423-0600; www.jby.com; East Coast Yacht Sales, 978-744-7070; www.ecys.com