Those of us of a certain age will remember back in the late 1960s when 7UP labeled itself “the uncola” to separate from the soft-drink pack. We might steal the phrase and label the Alpha 87 ES (Express Sportbridge) the “un-Cheoy.”

Even the cognoscenti, those who can name any boat at a thousand yards, will take a long time to tag the Alpha 87 with the Cheoy Lee brand name. Not because she isn’t beautifully built, thoughtfully designed and impeccably finished. No, she is all of those things and more.

Cheoy Lee, shipbuilders to the world since 1870, have launched an eclectic variety of commercial ships in all styles, from ferries and offshore fishing vessels to the tugs that nurse ships through the Panama Canal.

But when it comes to yachts, Cheoy Lee has had more conservative tastes, with motoryachts, expedition yachts and even megayachts that bore a distinctive Cheoy Lee “look” dating back to designer Jack Hargrave’s days, with none of the gewgaws and swoops that mark many yachts.

No more. The Alpha 87 serves notice that not every Euro-style express yacht comes from Euroland. You want to know how un-Cheoy Lee this yacht is? I walked past her on the dock and had to be called back for our test run!

The builder brought Michael Peters aboard to design this yacht, and that should tell you something. Peters has built a reputation for creating yachts that all have a common denominator: speed.

Another telltale pops up with Gene Weeks, the Alpha project manager. Weeks is a “hot boat” guy with companies like Donzi, Fountain, Outerlimits and Baja on his resume.

To put the frosting on this cake, Cheoy Lee had Luiz de Basto design the interior. He was given free rein to arrange and style the interior with one caveat from B.Y. Lo, the U.S. director of Cheoy Lee: “Make it the best.”

This talented trio is a potent combination in the highly competitive market for large express cruisers. They created an offering that is, first, styled and finished for the very upper end of this market; second, competitively priced with yachts of lesser quality; and, third, fast.

This is a four-stateroom yacht that tops out at 32 knots and that has gorgeous lines from the slightly reversed sheer to the swept-back house that seems to be doing 30 knots even at rest.

Her interior is straight out of Architectural Digest. Even better, she has some truly remarkable features, including a hidden cockpit hot tub and an ingenious launching system for the 12-foot tender in the garage.

Peters designed prop pockets in the 17.5-degree deadrise, so she draws just over 5 feet but also handles lumpy seas easily.

Inside, de Basto created a salon that seems to stretch endlessly in all directions with large sliders aft, huge windows on each side and even larger windows forward at the helm.

The interior is more megayacht than express cruiser with leathers, metals, finishes and woods that you’d never find on production yachts. With the flood of light, de Basto was able to use dark wenge underfoot, glossy black lacquer accents and zebrawood on the cabinetry.

Known in Europe as zebrano, zebrawood has striking light and dark bands that give it the name, and the Cheoy Lee craftsmen turned it into flawless tables and cabinetry.

The dining table, forward in the salon, is too beautiful to sully with even the finest place mats. Need a little fresh air? Touch a button and a huge sunroof slides open to allow dining under the stars.

In keeping with an alfresco lifestyle, the galley is aft for convenient access to the cockpit, with Bosch appliances and ample counter space not only outboard, but also on an island that hides a pop-up TVfor guests on the leather settee.

Just past the dining area are three raised seats that delineate the helm. These aren’t just any seats; they’re a trio of infinitely adjustable and comfortably bolstered Recaro products, which auto aficionados know are original equipment on exotic cars from the Aston Martin to the Ferrari.

The helm, which floats above the dual stairwells to the foyer below, is impeccably finished in leather and, on my test boat, was fitted with three monitors that display the Caterpillar engine instrumentation, the Furuno electronics and an InteliSea alarm-management system linking everything from bilge alarms to lights.

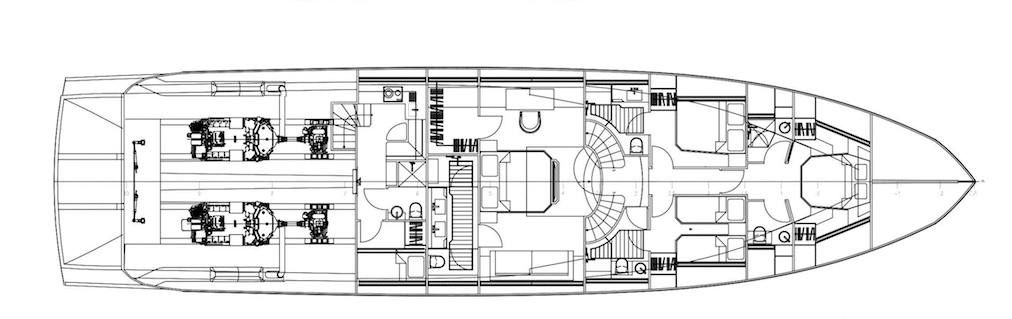

Descend via either of the two curved stairwells to the foyer, which is a sky-lit atrium with the windshield far overhead. Step aft into the full-beam master suite, and you’ll find a continuation of de Basto’s stylings in black lacquer and zebrano with large windows and a walk-in closet with built-in bureau.

The VIP is forward with a split en suite arrangement that puts the loo to port and an oversize shower to starboard.

Off the passageway is a double stateroom to port and a guest cabin with twins to starboard. Each is en suite, and the starboard head doubles for day use from the foyer.

I have to mention the marblework throughout, but especially the soles in the showers, which are intricately slotted for drainage and to megayacht quality.

This yacht’s big cockpit is a design-it-yourself area that, on my test boat, had been fitted with a settee and table across the transom with a second couch under the overhang forward.

What first appears to be a sun pad behind the settee is actually a concealed hot tub with wraparound seats. Other choices for this space would be an outdoor kitchen with barbecue or an open space simply for sun chaises.

The crew on the Alpha 87 live well, indeed, with quarters accessed through a door tucked under the bridge ladder.

Finished to the same standards as the guest areas, the crew space includes a mess with galley, dinette and entertainment, a cabin with two bunks and a head with shower.

The crew area opens to the engine room, and here you see Cheoy Lee’s experience in every seamanlike detail, from the carbon-fiber-capped stringers with stainless-steel engine beds to the dual-stage oil filters that can be changed while running.

All the coolant piping on the saltwater side is cupronickel (copper-nickel), making it poisonous to barnacles and protecting the engines from coolant starvation.

Other high points are the diamond-plate walk-arounds, the carefully manifolded fuel system, a beautifully engineered electrical panel and a workbench.

My test boat had the standard 1,900-horsepower Caterpillar C32 ACERT diesels and, though 2,600-horsepower MTU 16V 2000 M94 diesels would give another 4 to 5 knots, I felt the Cats were the perfect combination of speed and economy.

| Specifications | Builder Supplied Numbers |

|---|---|

| LOA: | 87’1″ |

| BEAM: | 21’7″ |

| DRAFT: | 5’7″ (full load) |

| DISPL.: | 153,200 lb. (full load) |

| FUEL: | 1,800 gal. |

| WATER: | 330 gal. |

| DEADRISE: | 17.5 degrees |

| ENGINES: (opt.): | 2 x 2,600 hp MTU 16V 2000 M94 diesels |

| PRICE: | Upon request |

Twin Onan 32 kW gensets in sound boxes easily handle the power loads, and our boat was fitted with a Humphree automatic blade-style trim tab system, bow and stern thrusters, and ZF joystick controls for maneuvering.

My boat also had the optional launch system for the 12-foot tender, and it’s both simple and foolproof.

Instead of permanent rails that mar the stern platform, the 87 has two flip-up covers over a runway for the wheeled dolly that carries the tender. Launching and retrieving is a one-person, button-pushing affair. Clever.

The sport bridge is straightforward with a pair of pedestal helm seats behind a fiberglass console that follows the lower helm with two monitors.

A venturi windscreen forward and sweeping fiberglass “wings” keep the breeze off anyone using the large sun pad, but I suspect sun worshippers will head to the foredeck.

There they’ll find an even larger sun pad plus wraparound couch seating that is perfect at anchor or when gently underway on nice days.

Speaking of underway, the 87 is just plain fun. The Peters hull feels light and nimble, and there’s plenty of kick from the twin Cats if you want to go fast.

When the GPS pushed past 30 knots, Weeks (a guy more used to speeds exceeding 100 mph) couldn’t stop grinning. And, knowing Weeks, I suspect he’s going to tinker with the props to get just a few more decimals.

| RPM | KNOTS | GPH | dB(A) |

|---|---|---|---|

| 600 | 6.3 | 4.0 | 68 |

| 900 | 10.8 | 19.0 | 68 |

| 1200 | 12.5 | 40.0 | 70 |

| 1500 | 19.4 | 71.0 | 72 |

| 1800 | 22.5 | 120.0 | 74 |

| 2100 | 27.9 | 169.0 | 76 |

| 2315 | 30.8 | 194.0 | 76 |

She’s happy at lower speeds too. At 1,750 rpm, the 87 ran at more than 20 knots, and at 1,430 rpm (and still on plane), she made an easy 15 knots at around 50 gph. Not bad for moving 75 tons of luxury at a good clip.

It was a nasty day in the Gulf Stream, but the 87 ate it up and asked for more. No spray on the bridge in spite of square-edged seas, and spinning the wheel at full throttle resulted in a solid and predictable banked turn that wouldn’t scare Aunt Edna.

With the Alpha 87’s resin-infused carbon fiber and E-glass foam-core hull, she is one tough yacht, and, in spite of her stylish looks, she’ll bring you and yours home in comfort on those days when many won’t leave the harbor.

I loved the Alpha 87 ES. She makes a statement that there is a new player in the big express market, and with impeccable finish, thoughtful detailing and seamanlike construction, she’s a breath of fresh air. The un-Cheoy.

Building Blocks

A noticeable feature of the Cheoy Lee Alpha 87 ES was the mirror finish, particularly since my test boat had a blue hull and areas on the superstructure in either black or silver. All of these colors tend to magnify any imperfection of the fiber-glass, but there were no ripples or lumps where bulkheads were joined to the topsides. I wanted to find out how the company did it.

Gene Weeks, Alpha-series project manager, explains the process Cheoy Lee used to create the Alpha-series molds. The starting point was two sets of drawings from naval architect Michael Peters: a two-dimensional set for reference and a three-dimensional set of numbers recognizable to the Cheoy Lee five-axis, computer-driven router.

“We take the hull shape,” says Weeks, “and slice it into cubes that can fit into our CAM router. Each cube starts as a rigid steel frame, and on the outer side, we cover it with a high-density material the workers call doy mok, meaning “not wood.”

Applied in sheets, the doy mok is extremely stable, and each cube is cut to the hull shape using the router.

Most builders use a low-density foam to build the hull plug and then slather it with putty, followed by hand sanding to the final shape. The result is time-consuming and often results in a hull with high and low points.

Once the cubes have been cut to shape (and numbered), Cheoy Lee workers fit them together like building blocks to create the hull plug. Because of the precision routing, all that remains is to fill the tiny gaps and spray on gelcoat.

From this finished plug, the female hull mold is created and Alpha-model hulls are then laid up with resin-infused fiberglass.

On the smaller Alpha 76, Weeks notes, the process required 109 cubes, which were created at the rate of three per day, thus allowing a much shorter time to go from drawings to a finished hull.

For the Alpha series, every component — hull, deck, house and small parts — was created using this cube method. The result is a perfectly fair and flawless finish on the Cheoy Lee Alpha 87 ES. — C.C.