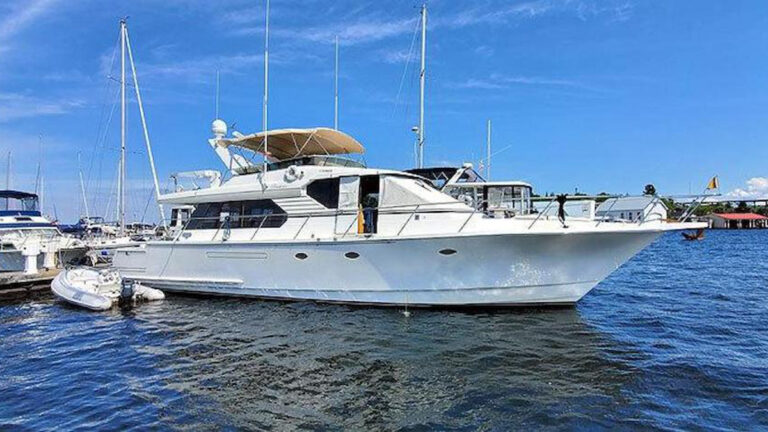

David B

We began our restoration of the David B by removing the foredeck. On our first day, we arrived on Lopez [Island, Washington] early, armed with crowbars, a couple of hammers, a Skilsaw, a Sawzall, and a lot of enthusiasm.

Jeffrey stood at the port bow of the boat. “Well, here it goes,” he said, and kneeled down to the deck. I stood over him and watched as he swung the prying end of his hammer. It made a dead thud into the soft wood. He pulled the hammer back again and swung.

“Ready for a crowbar?” I stood with the smaller one in my hand.

“How about the Skilsaw instead,” he said.

Jeffrey made the opening cut and then pried out the first foot of decking. He handed me the hammer and small crowbar, then explained a couple tricks for removing the deck planks. I went to work while Jeffrey moved aside to begin opening up the starboard side of the deck.

Our crowbars dug easily into the planking and tore up the soft wood, ripping and splintering old rotten decking and tar-coated plywood. The Sawzall was hungry that day. Its vibration in my hands was like the purr of a satisfied cat after a kill. The teeth of its bi-metal blade cut through the deck like butter, only occasionally slowed by an ancient fastener.

_View a photo gallery of the David B’s restoration._

By midday the sun was hot. I was dirty, and the T-shirt and shorts I wore were filthy. My skin was sweaty and coated red with a fine film of tar dust, sawdust, and rust dust. Under the noonday sun, I smelled like fungus, rusty nails, wood, and asphalt. That smell is forever imprinted in my mind.

As I lay on the foredeck thinking about that first day, I breathed deep, in search of that smell. It’s gone now, replaced with new fir, fresh plywood, and deck oil. Sometimes I catch a whiff of that timeless smell, usually tucked in hard-to-get-to places like the anchor chain locker or the bilge. The smell of the David B‘s age lingers in its timbers, reminding me that with a wood boat, no restoration is ever complete.

Eight years ago, with my Sawzall and pry-bar, I was foolishly confident. But as we worked, doubt began to creep into my soul. This project might be too big fluttered across my mind as I pulled away rotten deck and watched Jeffrey’s body language. Nah, Jeffrey knows what we’re doing. It’s going to be all right. We’ll get this done, I reassured myself even as I noted that with each cut of the saw, we found more and more rot.

Where we thought we could simply remove the tarred plywood and sand down the original decking, we discovered that there was nothing underneath we could save. We held out for months that some of the planks near the mast were sound.

As we removed the deck planking and exposed the tops of the deck beams, we discovered that they too were rotten and would need to be removed and replaced. Late in the afternoon on the first day, I stood on the main deck next to the bone pile of deck planks and beams.

“Hey, what are we going to do with all this wood?” I called out to Jeffrey, who was down below.

“Jeremy said we could put it over on his burn pile on the shore,” he replied from low in the anchor-chain locker.

“Everything OK down there?” I peered down into the opening where the deck had been.

“Yeah, I think so, but I’m afraid we’re going to have to remove the beam shelf as well. It’s pretty far gone,” he said, with a mix of disappointment and conviction.

I picked up an armload of wood and headed to the beach. Two years to have the boat ready. I sure hope we don’t find anything else wrong.

***

Launching the boat from the shipyard that first time was a huge thrill, but, like so much that happened that year, it seemed like it was all happening too fast. We’d filed a copy of our brand-new insurance policy at the Port of Bellingham, so we were free to go back to our slip whenever we wanted, but I didn’t feel we were ready. I knew Jeffrey was anxious to get the boat back because the cost of staying in the shipyard was so high, but it still surprised me when he made an appointment to launch the boat right away. To anyone else, the David B looked far from ready to go back into the water.

“We’re gonna splash next Saturday,” Jeffrey said, smiling.

“Seriously? Don’t you think that’s rushing things? There’s still so much to do. What about the bulwarks and sanding and painting the hull? Don’t forget you’re signed up to race the next morning. Are you all right with it being the day before Ski to Sea? You need to leave around five-thirty or six the next morning, that Sunday, to be at the run-bike exchange. Wouldn’t Monday be a better day?”

“No, Monday’s Memorial Day and the yard won’t be open. I think Saturday will work fine. As far as the work that needs to be done, we’re finished with everything below the waterline other than paint. We can do everything else when we’re back at the dock.”

Our workdays that last week at the shipyard got longer and longer. By midweek, we were working from five in the morning until nine at night. I gardened for seven or eight hours each day, then drove to the yard to sand and paint. There was no time to cook, so we ate pizza. When we didn’t order it ourselves, friends and neighbors would stop by with it. Then they’d spend a few hours painting with us. I never thought I could ever tire of pizza, but I did that week. The feeling of nearing our launching date was electric. The best day was when we removed the cover. Seeing the whole boat for the first time in almost six months gave me shivers. Its hull was beautiful, especially the stern, where most of the new construction had taken place.

***

The day before we were to launch the boat, Jeffrey was called into the office at the shipyard. They were sure we weren’t ready and wanted us to reschedule, but Jeffrey insisted that we were. It seemed funny to me that they didn’t want us in the yard when we hauled, and now they didn’t want us to leave.

We continued our mad rush to get the last details of our shipyard time finished. We worked on painting, frames, planking, and through-hulls. Aaron spent hours polishing the propeller. Jeffrey went over his lists again and again to make sure we had everything finished and there wouldn’t be some important detail left behind.

On Friday, as the daylight faded, we worked into the dark by shop lights to finish the last coat of topside paint. Just after eleven p.m., Jeffrey called for us to stop work. Like students cramming for a final exam, we had finally had enough. The_ David B_ sat silently in the dark, shining with new paint, new frames, new planking, and a second life.

I snapped a picture that would forever sum up our last day in the shipyard. It’s really nothing special, just a bunch of guys standing around in the dark with beer bottles in their hands. The boat isn’t even in the photo. I love the image for what it means to me, the moment in time where the balance shifted. In that instant on May 27, 2005, we all stood back and took in the work we had done. We had saved the David B.

_View a photo gallery of the_ David B_’s restoration._

Christine and Jeffrey Smith own and operate the David B as a charter vessel running between Bellingham, Washington, and Juneau, Alaska. For more information on chartering, visit www.northwestnavigation.com_._ More Faster Backwards_ is available for purchase at_ www.amazon.com_