Beyond the Hype

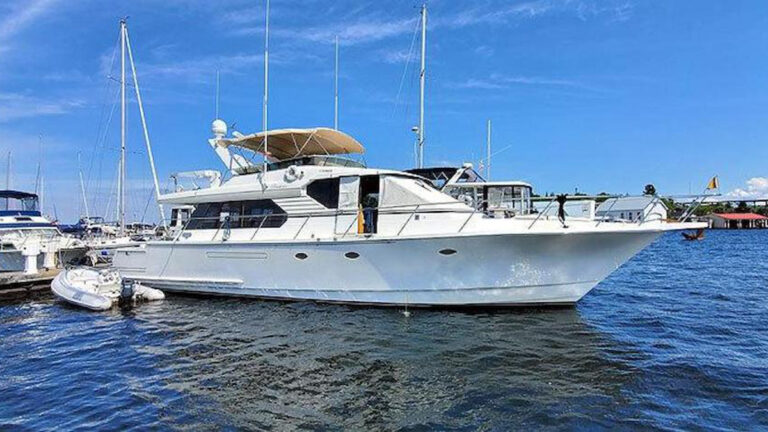

Pod drives have been widely available only since 2007, yet they have the market awhirl. Sabre Yachts, for example, first offered pods in 2008 as an option over straight shafts in the 42-foot express cruiser. The company has built exactly one 42-footer without pods since, versus a dozen boats with the pods option and another 50 of the new, pod-only 42-footer. “The noise and smell from a diesel goes away with pods,” said Bentley Collins, Sabre’s vice president of marketing and sales, “and with joystick control, you don’t have to worry about crashing into the dock.”

Pods also increase fuel economy and decrease vibration. But now that both Volvo Inboard Propulsion System and Cummins MerCruiser Zeus drives have been spinning beneath boats for more than five years, it’s time to assess the cost of ownership of pods versus conventional shafts.

“There is definitely more maintenance with pods,” said John Siebert. His company, Siebert Yacht Management commissions and maintains most new Sabre boats delivered to Palm Beach County, Florida, giving him considerable experience with Volvo IPS drives on Sabre’s 38- and 54-foot models and with Cummins Zeus drives on Sabre’s 42- and 48-footers, as well as those same hulls with conventional shafts.

To start with, Zeus and IPS boats have to be hauled after their first 25 engine-hours. “Cummins says you don’t have to haul, but it takes a lot more time to suck that heavy oil out than to just drain it from the bottom,” Siebert said. Volvo doesn’t offer the option of in-water service. “Plus, when we haul the boat, we’ll catch problems a diver won’t see.”

“For those first 25 hours, we use a break-in lube,” said David Fessenden, a marine applications engineer with Cummins Atlantic. “That smooths out some of the minor gear asperities and grinding marks, improving the life of the gears.” After break-in, pods are serviced every 250 hours or 12 months, whichever occurs first.

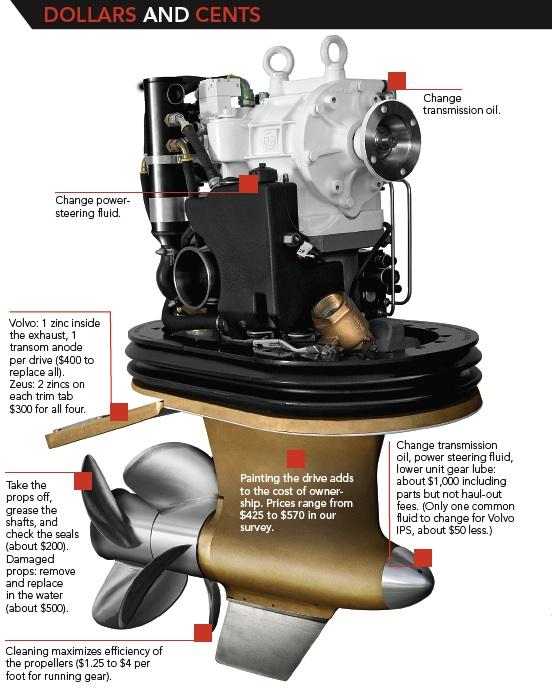

“Take the props off, grease the shafts, and check the seals,” Fessenden said. Zeus propeller shafts use a double-lip seal. If the outer seal is damaged by debris, fishing line or rope, only the inner seal separates the pod’s innards from seawater. “Look for signs of corrosion.” Zeus has two zincs attached to each trim tab. Volvo has one zinc hidden, but accessible, on the drive itself. “If you seem to be going through zincs quickly, call an electrician,” Fessenden warned. Use Volvo or Cummins zincs too, which aren’t zinc at all. Cummins uses aluminum-gallium anodes to best protect bronze drives.

On Cummins drives, standard-equipment MerCathode system anodes emit a tiny electrical charge opposite the damaging electrical currents that normally flow through metal parts in seawater, actively protecting pods from galvanic corrosion. Volvo’s Active Corrosion System, which is standard on IPS 800 or larger drives, is similar. Those anodes shouldn’t dissolve like zincs do, but both systems should be checked annually.

“If your zincs are gone, your warranty might be gone too,” Siebert said, so all his clients’ boats with pods are cleaned and checked monthly by a diver. Cleaning also maximizes efficiency of the pods’ contrarotating propellers.

Warranty concerns may shorten the list of service providers. “Not a lot of guys know pods yet. Make sure they’re specifically trained, or at least have several years of experience,” Siebert said. Zeus service includes changing 0w30 SAE transmission oil, hydraulic steering oil and filters inside the hull as well as 90-weight gear oil outside the hull. Volvo uses SAE 75w140 oil for both the transmission and lower unit. Zirk fittings require grease in U-joints and at both ends of jack shafts that connect engines to drives.

Painting pods will cost a bit more too. “We get a lot of oyster growth inside the drive intakes,” Siebert said. “You can’t take the grate off to clean or paint in there.” His solution is to spray Interlux Trilux 33 or Pettit Alumaspray Plus from aerosol cans inside the seawater intakes. Siebert removes all loose paint from the drive, sanding down to shiny metal with 100-grit sandpaper, and then applies primer and two thin coats of Trilux 33 or Pettit Vivid copper thiocyanate anti-fouling paint.

Pods also expand morning fluid checks to include the lazarette. When checking transmission oil level, give it a sniff. The pods’ synthetic oil is dark, making it hard to see the telltale oil discoloration of a slipping transmission, but it will likely have a burnt smell. On Zeus drives, check the steering oil reservoir dipstick, and check the clear reservoir for lower-unit gear oil for any signs of water seeping into the drive. “If you lose oil or get water in the lower unit, an alarm will sound before the problem becomes catastrophic,” Fessenden said of Cummins drives.

Volvo includes neither a water alarm nor a clear reservoir, so check the single transmission and gear oil dipstick for signs of water. If water is suspected inside any pod, get a mechanic aboard right away or risk internal damage.

It’s also important to monitor for seawater dripping onto drives. “Our drives are made to stand up to a light freshwater rinse,” Fessenden said, “but don’t blast them with the hose.” Fessenden suggests a light coating of Mercury’s corrosion spray. Siebert prefers Boeshield T-9.

Siebert puts annual maintenance for pods roughly $2,000 above what straight shafts cost, not including extra haul-out fees for boats that exceed 250 engine-hours per year. On the other hand, pod boats typically don’t have bow thrusters. They also don’t have cutlass bearings or shaft seals to monitor and replace, nor separate rudders and steering systems to maintain, saving money on those items over the long haul.

A very hard grounding is also likely to cost less with pods, since they’re meant to shear off and then go right back onto the boat with just a thorough service and new bolts. When one of Siebert’s clients hit a sandbar, “it happened so smoothly that he didn’t even realize he’d lost drives until he revved the engines and the boat didn’t respond,” Siebert said. His experience tells him a similar grounding with conventional shafts would have been much worse, perhaps even damaging rudder or strut supports badly enough to flood the boat.

On the other hand, touching bottom only hard enough to bend the propellers will likely cost more on pods, because they have two props to repair on each drive. Somewhere in between the cost of straightening conventional shafts and rudders, and possibly even repairing transmissions, the advantage shifts back to pods.

Fuel savings can be weighed against additional maintenance, but economy varies with each boat and depends on how it’s used. (See “How Fuel-Efficient Are Pods, Exactly?”) The biggest savings might come when the pods’ aft-located engines add interior accommodations. The pod version of the 42 Sabre, for instance, adds a queen bed and more stowage to the guest stateroom, as well as the option for a washer and dryer. When a 42-foot pod boat can replace a 46-footer, savings add up fast. It’s also hard to put a price on joystick control, which completely changes dockside handling. Sociability is another huge advantage to pods. “They’re a whole different animal,” Siebert said. “For people who have been boating for 30 years, the quiet, smooth operation and the clean exhaust are really going to surprise them.”

But Collins thinks the pod’s advantages are even less quantifiable. “Pods are something new,” he said. “They get people excited about buying a new boat.”

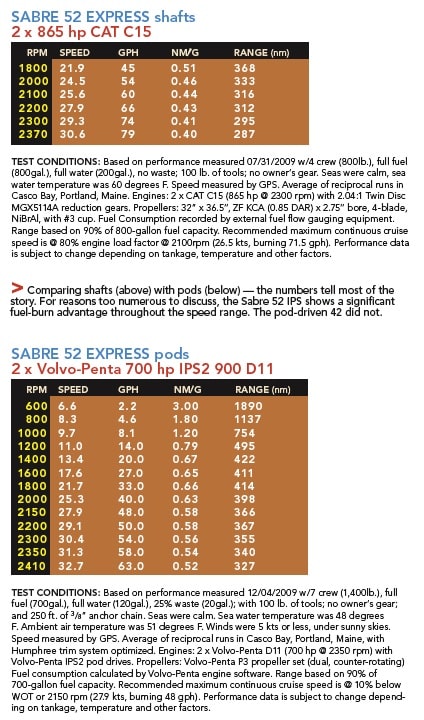

How Fuel-Efficient Are Pods, Exactly?

Comparing the Sabre 42 Hardtop Express, one with pods and one with shafts: At wide-open throttle, the pods’ horizontal thrust and contrarotating propellers increase economy (0.8 nmg for pods, 0.63 nmg shafts). But downward-pointing conventional shafts lift sterns, negating, or even reversing, that fuel-economy advantage at slower speeds (0.92 nmg shafts @ 15.9 kts. vs. 0.8 nmg pods @ 16.2 kts.). Most pod boats burn roughly the same per mile through a wide range of cruising speeds; conventional shaft boats typically have a narrow sweet spot. Savings on a long haul might disappear when slowing to navigate a tricky channel or speeding up to avoid a storm. Naval architects have also gotten better at maximizing the efficiencies of pods at all speeds.

Drive Pirates

When pods shear off, their recovery might cost a huge percentage of their value. “Mark their location any way you can, with a waypoint or a buoy,” said Steve Little, president of TowBoatU.S. Charleston. “If we can go straight to them and safely lift them into the boat, most tow boat operators are going to charge an hourly fee or a flat fee, and not claim salvage. If we have to go searching or put divers in the water, that’s another story.” To prevent later claims of piracy, “come to an agreement beforehand,” Little said.

When pods vibrate, propellers or jack shaft bearings are the likely causes. To determine which, run the throttle up slowly on one engine and then the other. If one engine vibrates but the other doesn’t while in neutral, the problem is likely in the always-turning jack shaft. If one engine vibrates in gear and the other doesn’t, it’s probably caused by fouled or damaged props.

Your Thoughts?

Do pods make a boat easier to handle in all conditions and situations? Weigh in with your experiences here.

Battleground

To read more about pods and see side-by-side comparisons, click here.